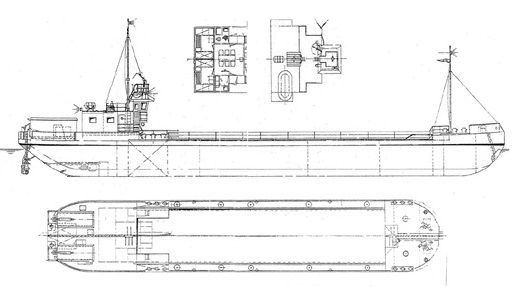

The barge consists of two half-hulls connected by hinges at the top and hydraulic cylinders at the bottom. After unloading the housing halves are moved back together due to the shape and structure and rods retract cylinders.

Split Hopper Barge Tiger Discharging At Sea Youtube

Homar can deliver the design of split hopper barges Homar bv.

. The design is a 3800 m3 push. A barge is a type of ship which is mainly used for the purpose of carrying cargo. Homar bv is a versatile Project Management company for Shipbuilding Dredging Offshore Industry.

A Self-propelled Split Hopper Barge is a vessel with a large open hold used to load and transport dredged material. Split hopper barge is of reliable ihc design and suitable for all kinds of dredging works We can offer design for split hopper barges adversisement splithopper bargespdf 80328kb we can offer design for split hopper barges. When sailing the parts are kept closed by a number of locks.

I am planning to analysis below loading conditions. The hinges and cylinders must transfer any forces that act at the interface between the half-hulls. SEYMOUR CLASS The Seymour Class of split hopper barges are 55m in length capable of hauling 1500 cubic yards 1150 cu.

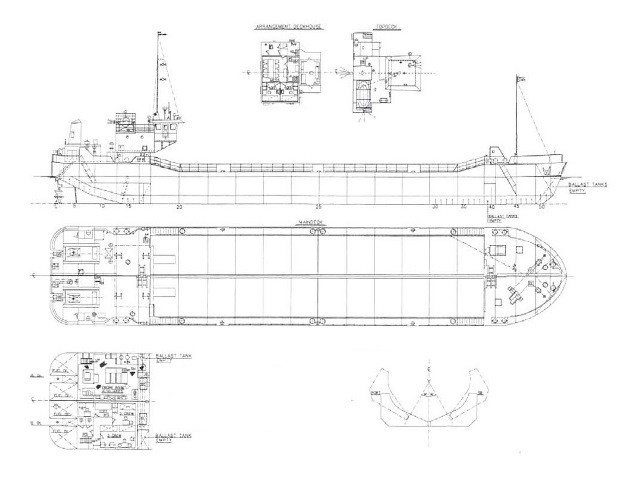

Due to the barge carrying soil and application of a larger proportion cut the superstructure living facilities and equipment layout is simpler so the ship design in terms of space and layout is easy to meet this is. 2017-10-16 Abstract A split hopper barge is a dredging vessel that can split over its longitudinal axis to discharge its cargo. An overview of recent split hopper barges projects.

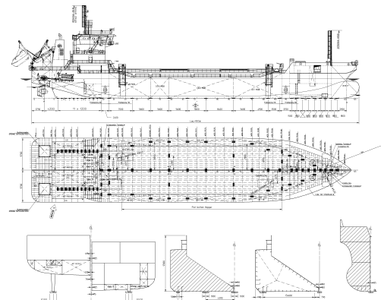

Splithopper Barges SPLITHOPPER BARGES RECENTLY COMPLETED THE DESIGN of a 2375 m3 SPLITHOPPER BARGE and working on a design of 1000 m3 Splithopperbarge HOMAR BV acting as owners representative providing following services. The barge is usually loaded by any type of dredger usually a Cutter Suction - a Backhoe - Grab or Bucket Dredger. The hopper slopes of 35 degrees along with an opening of 24 degrees ensures a clean dump of whatever waste material is being hauled.

A split hopper barge is a dredging vessel that can split over its longitudinal axis to discharge its cargo. When loaded the vessel sails independently to the deposit area where it unloads the materials. Vessel with a large open hold used to load and transport dredged soil.

The hoppers may be covered or open. One adjustable overflow is fitted close to aft end of hopper. 200 m3 capacity split barge.

Our split hopper barges are used all over the world for dredging pile-driving and drilling projects. The barge is self-propelled and sails to the deposit area where it. The design is a 3800 m3 Push Spilt Hopper Barge redesigned from a towed Split Hopper Barge.

Trasporting all kinds of dredged and other bulk material. Hopper barges have a boxed single raked or double-raked hull configuration. Split Hopper BargeSplit Hopper Barge DesignSplit Hopper Marine Barge.

At your service Home. Split hopper barge A split hopper barge is a vessel used for installing soil sand or stones. 160 m3 capacity split barge.

SEYMOUR CLASS Capilano Maritime Design Ltd. 2 0100 0548 078. Adarsh Edakkote Junior Member.

Wide bottom opening of 5. M of waste material in their hoppers. - Preliminary design - Tender package - Basic design - Yard selection - Building supervision - After sales services.

Covers provide protection of cargos from outside elements. 1Lightship condition Hopper closed and open 2Fully loaded condition. 7800 x 1600 x 560 m.

If anyone is expertise in split hopper barge stabilityPlease revert to below. Powered by two hydraulic cylinders the bottom of the barge splits like a grab. The barge is loaded by a Cutter Suction Dredger or by a Backhoe Dredger.

To allow for such an operation the barge consists of two half-hulls that are connected by hinges at the top and hydraulic cylinders at the bottom. Welcom at our website. 2 0122 4259 344 EN.

The vessel is constructed for unrestricted operation worldwide. 940 m3 Split Hopper barge Dnouglubitel from dnouglubitelru. 160 m3 capacity detachable split barge.

These barges are designed for efficient transport of commodities in bulk such as grain coal sugar ore steel aggregates timber products and numerous other cargos. However the most important part about barges is the fact that they are not. SPLIT HOPPER BARGE DESIGNS A split hopper barge is a vessel with a large open hold used to load and transport dredged material.

57 Port Fouad - Port Said - Egypt 2 066 3400 598 2 066 3400 471. Split hopper bargeThe D14 design is a self propellered split hopper unit with hopper capacity of 2800 m 3. We have a variety of Split Hopper Barges for Sale new used propelled or non propelled ranging from 300m3 capacity to over 2000m3.

Allow for such an operation. The split hopper is 1920 x 396 with capacity of about 3800m3. Analysis of the Split Hopper Barge when design.

When passing the housing halves barge divided longitudinally and load reset spontaneously due to the shape and design of the vessel. I have some doubts regarding the stability analysis of split hopper bargeI have auto hydro software with me. With their propulsion capacity of 2 x 1825 kilowatt the pushbusters are also suitable for towing.

Split Hopper Barge Ganz Danubius Huti

1 000 M3 Self Propelled Split Hopper Barge 2 Sisters Van Loon Maritime Services B V

Concept Design Projects Marino Consulting Naval Architecture And Marine Engineering Company

160 M3 Non Propelled Split Hopper Barge 2 Sisters Van Loon Maritime Services B V

Dumb Barge Split Hopper Barge Accommodation Barge Offshore Barge Designs India

Sweden Fkab Improves Split Hopper Design Shipbuilding Seanews

0 comments

Post a Comment